The Growing Problem of Scrap Tire Waste

Mounting Volumes of End-of-Life Tires

The global production of tires continues at a staggering rate, with over 1 billion tires reaching the end of their useful life each year. This results in significant environmental challenges, as approximately 300 million scrap tires are generated annually in the U.S. alone. These discarded tires often end up in landfills or illegal dumping sites, contributing to mounting waste issues. The accumulation of scrap tires poses serious environmental risks, such as disruption of local habitats and providing breeding grounds for pests and mosquitoes, which can lead to health hazards. Addressing this growing problem is essential to mitigate these ecological impacts and promote sustainable waste management practices.

Traditional Disposal Methods and Their Limitations

Traditional methods of scrap tire disposal, such as landfilling, incineration, and stockpiling, prove to be ineffective and environmentally harmful. Shockingly, about 50% of tires still end up being disposed of improperly, contributing to pollution and health concerns. Landfills pose significant threats to the environment, with leachate from scrap tires potentially contaminating groundwater and surrounding ecosystems. The current regulatory frameworks often lack enforcement, leading to increased illegal dumping and inadequate tire waste management. To counteract these issues, a shift towards sustainable and circular waste management practices is essential for reducing the ecological footprint of scrap tire disposal.

How Waste Tire Pyrolysis Works: The Thermal Decomposition Process

Key Stages in the Pyrolysis Conversion Process

Pyrolysis of waste tires is a transformative process consisting of four main stages: drying, pyrolysis, cooling, and collection. Each stage plays a crucial role in efficiently converting organic materials into reusable resources. During the drying phase, tires are prepped by removing moisture content, enabling optimal thermal decomposition. The actual pyrolysis follows, where high temperatures break down the tire's organic compounds into a mixture of gases, liquid, and solid residues like char. Cooling is then applied to differentiate and stabilize these Products.

Thermochemical changes during pyrolysis are significant; they result in gaseous, liquid, and solid products. The ideal temperature range for efficient pyrolysis is typically between 400°C and 700°C. At these elevated temperatures, tires break down, yielding gases that can be further processed into fuels, oils that can be refined or reused directly, and char which has applications in the manufacture of other materials. Understanding these stages and their dynamics is essential for maximizing the efficiency and yield of the pyrolysis process.

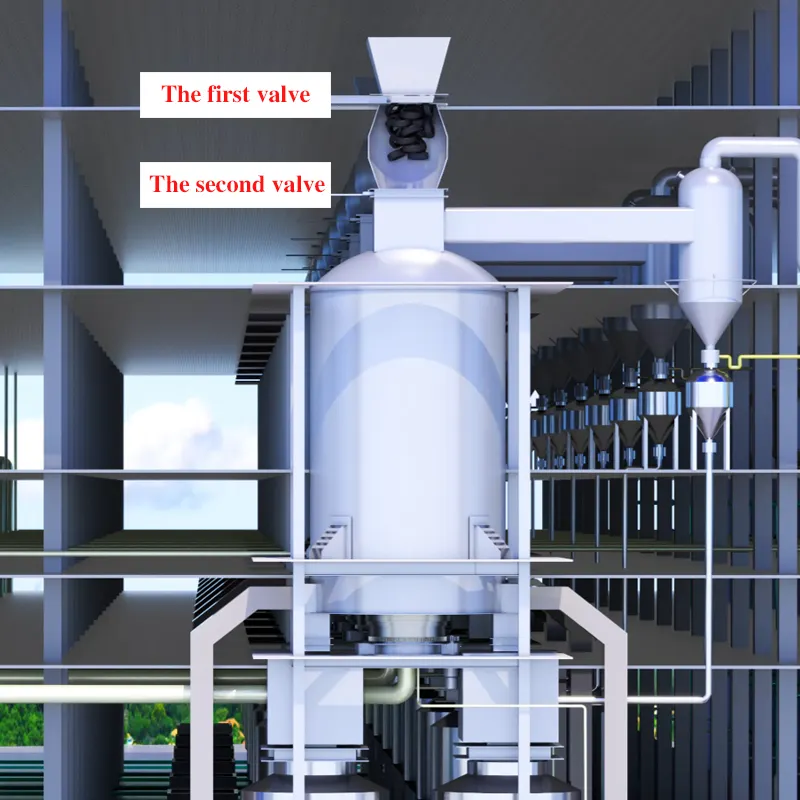

Advanced Reactor Designs for Efficient Decomposition

The effectiveness of the pyrolysis process is significantly influenced by the design of reactors used. Innovative designs such as batch, continuous, and modular reactors have been developed to enhance heat transfer and boost energy efficiency. Continuous reactors, for instance, provide a steady and uninterrupted feed of waste tires, optimizing thermal decomposition and ensuring consistent product recovery rates. Modular reactors, on the other hand, offer flexibility to scale operations up or down, catering to varying capacities and operational needs.

Several studies have shown that advancements in pyrolysis reactor technology result in higher recovery rates of valuable by-products. By improving the heat transfer rates and energy efficiency of reactors, industries can notably lower operating costs. These innovations not only benefit the environment by reducing energy input and emissions but also provide economic advantages through improved efficiency and product yields. The development of these reactor technologies is therefore pivotal in propelling the broader adoption and efficacy of waste tire pyrolysis as a sustainable waste management strategy.

Valuable Outputs: From Waste Tires to Reusable Resources

Recovered Carbon Black for Manufacturing Applications

Pyrolyzed carbon black is an invaluable byproduct obtained through the tire pyrolysis process and is widely used in the manufacturing sector, particularly in the rubber and plastic industries. This material features prominently in the production of new tires, industrial rubber goods, and plastics, where it serves as a reinforcement agent to enhance durability and performance. The market value of recovered carbon black is substantial, with estimates suggesting it could reach billions of dollars annually due to its cost-effectiveness and sustainability benefits. Companies like Liberty Tire Recycling and Contec have successfully integrated carbon black derived from pyrolysis into their products, demonstrating its utility as a sustainable material that helps reduce the carbon footprint of manufacturing processes.

Pyrolysis Oil as Renewable Fuel Source

Pyrolysis oil represents a promising renewable alternative to fossil fuels, primarily intended for energy production. Its high energy content makes it ideal for use in industrial settings as an alternative fuel, effectively decreasing reliance on conventional energy sources. For instance, cement kilns and paper manufacturers have incorporated pyrolysis oil into their processes to capitalize on its robust calorific value. According to recent industry reports, companies and municipalities across the globe are integrating pyrolysis oil into their energy systems, highlighting its versatility and potential as a sustainable energy source. Moreover, despite fluctuations in oil prices, the demand for pyrolysis oil remains consistently high due to its renewable nature and environmental compatibility.

Steel Wire Recovery and Industrial Uses

During the tire pyrolysis process, steel wire recovery is substantial, offering significant reuse in various industries. This process involves the separation of steel wires from end-of-life tires, which can account for up to 20% of the tire's weight. Steel recovered through pyrolysis is utilized in construction, automotive, and other industrial applications, contributing to a more circular economy. Reprocessed steel wire not only reduces waste but also provides an economically viable source of material. Industries can benefit from the cost savings associated with using recycled steel, promoting sustainable practices and encouraging further innovation in material reuse within the industrial sector.

Environmental Benefits of Tire Pyrolysis Technology

Reducing Landfill Contamination Risks

Tire pyrolysis technology significantly reduces the environmental impact of scrap tires, particularly their deposition in landfills. By adopting pyrolysis, we can effectively address the issue of landfill space consumption and the leachate contamination associated with decomposing tires. Scrap tires in landfills pose considerable risks, including the potential release of toxic substances and greenhouse gases. The process of pyrolysis converts waste tires into valuable byproducts, such as carbon black and pyrolysis oil, thus diminishing these risks. According to a study by the European Tyre and Rubber Manufacturers' Association, nearly 95% of waste tires in Europe were diverted from landfills for recycling and energy recovery in 2019. By processing tires before they reach landfills, pyrolysis not only saves critical landfill space but also nullifies the harmful environmental repercussions traditionally associated with tire disposal.

Lowering Carbon Footprint Through Resource Recovery

Resource recovery through tire pyrolysis plays a pivotal role in lowering the carbon footprint associated with waste management. Compared to traditional methods like incineration or landfill deposition, pyrolysis offers a more carbon-efficient solution. Life cycle assessments of pyrolysis demonstrate significant reductions in greenhouse gas emissions. For instance, while burning tires for fuel in cement kilns can lower some emissions compared to fossil fuels, pyrolysis nearly eliminates the release of harmful gases by converting them into reusable resources. Studies show that pyrolysis can reduce carbon emissions by as much as 60% when compared to standard disposal methods. Such data underscore the ecological advantages of adopting pyrolysis technology for tire waste, thereby cementing its role in creating a sustainable and circular economy.

Economic Opportunities in the Tire Recycling Industry

Job Creation in Green Technology Sectors

The rise in demand for innovative recycling solutions has opened up significant job opportunities within the tire recycling industry. As tire recycling becomes a pivotal aspect of environmental conservation, it creates roles for technicians, engineers, and researchers who specialize in green technology. This burgeoning field addresses the intricate challenges of recycling to protect ecological systems. According to recent employment statistics, the green technology sector, including tire recycling, is witnessing a steady increase in job creation, with projections indicating a considerable growth trajectory over the next decade.

Monetizing Tire-Derived Products in Circular Economy

Integrating tire-derived products into the circular economy framework offers noteworthy economic advantages. By recycling tires, businesses can tap into market opportunities centered on products such as carbon black, pyrolysis oil, and steel. For instance, these materials are significant in various industries—carbon black is a crucial component in manufacturing new tires, while pyrolysis oil can serve as an alternative fuel source. Successful business models have demonstrated that leveraging these recycled tire products can yield sustainable profits. By remaking these waste materials into valuable commodities, companies can thrive economically while contributing to environmental stewardship.

FAQ

What is the main environmental problem associated with scrap tire waste?

The main environmental problem associated with scrap tire waste is their accumulation, which leads to habitat disruption, breeding grounds for pests, and health hazards. Improper disposal of these tires also contributes to pollution and contamination risks.

How does the pyrolysis process work in converting waste tires?

The pyrolysis process works by thermally decomposing waste tires in a series of steps: drying to remove moisture, high-temperature pyrolysis to break down organic compounds, and cooling to stabilize and collect byproducts like gas, oil, and char.

What are the valuable outputs obtained from the tire pyrolysis process?

The valuable outputs obtained from the tire pyrolysis process include recycled carbon black for manufacturing, pyrolysis oil as a renewable fuel source, and recovered steel wire for industrial applications.

What are the economic benefits of tire recycling?

The economic benefits of tire recycling include job creation in the green technology sector, reduction in material costs through resource recovery, and the potential for sustainable profits by selling recycled products such as carbon black and pyrolysis oil.

How does tire pyrolysis contribute to reducing landfill waste?

Tire pyrolysis contributes to reducing landfill waste by converting scrap tires into valuable byproducts, thus preventing them from ending up in landfills and cutting down on space consumption and contamination risks.

Table of Contents

- The Growing Problem of Scrap Tire Waste

- How Waste Tire Pyrolysis Works: The Thermal Decomposition Process

- Valuable Outputs: From Waste Tires to Reusable Resources

- Environmental Benefits of Tire Pyrolysis Technology

- Economic Opportunities in the Tire Recycling Industry

-

FAQ

- What is the main environmental problem associated with scrap tire waste?

- How does the pyrolysis process work in converting waste tires?

- What are the valuable outputs obtained from the tire pyrolysis process?

- What are the economic benefits of tire recycling?

- How does tire pyrolysis contribute to reducing landfill waste?