Megértés Az abroncsok pirolízisa

A kerékpárhulladék pirólizis kritikus technika a használt gumiabroncsok értékes árucikkekké történő átalakításához, a újrahasznosítási folyamat elősegítéséhez és a fenntarthatósági kezdeményezések támogatásához. A pirolízissel intenzív fűtés révén anaerob (oxigénmentes) környezetben bontják le a gumiabroncsokat. Ez a folyamat három fő részre alakítja át a gumikat: Termékek Az olaj, a szénfekete és a gáz. Ezek a melléktermékek elengedhetetlenek, mivel jelentősen hozzájárulnak a körforgásos gazdaság kezdeményezéséhez, mivel olyan nyersanyagot biztosítanak, amelyet újra be lehet integrálni a termelési ciklusba, különösen a gumiabroncs- és energiaiparban.

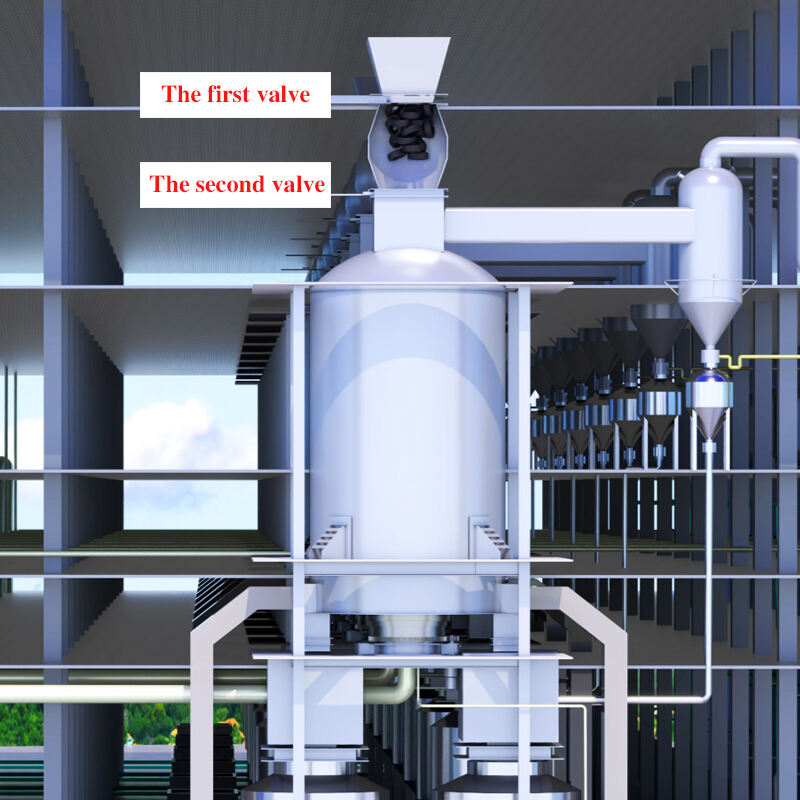

A pirolízissel a gumiabroncsok darabokra törésével kezdődik, amelyeket aztán oxigén hiányában magas hőmérsékletnek vetnek alá. Ez a hőelbomlás megváltoztatja a gumiabroncsok fizikai és kémiai összetételét, elsősorban gázállapotba alakítva, és szilárd maradványokat hagyva, mint például a szénfeketét. A pirolízissel előállított olajat, amelyet kerékpirolízisszel előállított olajnak (TPO) neveznek, finomítani és üzemanyag-helyettesítőként felhasználni lehet, míg a gázt az eljárás során energiaforrásként is felhasználni lehet, így növelve a hatékonyságot.

A gumiabroncs pirolízisének melléktermékei számos alkalmazást kínálnak, megerősítve a gumiabroncsok újrafeldolgozásában és hulladékgazdálkodásában játszott szerepét. A pirolízissel előállított olajat ipari alkalmazásokban lehet felhasználni, ezáltal csökkentve a hagyományos fosszilis tüzelőanyagoktól való függőséget. A szénfekete, egy másik melléktermék, a gyártási folyamatokban, különösen a gumiabroncsgyártásban, erősítő töltőanyagként vagy pigmentként felhasználható. Ez nemcsak csökkenti a hulladékot, hanem olyan fenntartható anyagforrást is biztosít, amely segíthet a gyártási műveletek szénlábnyomának csökkentésében, összhangban a jelenlegi globális fenntarthatósági célokkal.

A Az abroncsok pirolízisa

A kerékhulladék pirolízis számos környezeti előnyt jelent, amelyek a hagyományos kerékeltakarítási módszerek káros hatásait orvosolják. A felhasznált gumiabroncsok értékes termékekké történő átalakításával a pirolízissel jelentősen csökkenthető a hulladéklerakók használata, ami kritikus tényező, figyelembe véve az évente becsült milliárd gumiabroncsot. Ezenkívül ez a folyamat korlátozza az üvegházhatású gázok kibocsátását a hagyományosbb ártalmatlanítási módszerekkel, például a elégetéssel vagy hulladéklerakással összehasonlítva. A környezetvédelmi előnyök különösen figyelemre méltóak a körforgásos gazdaság modellje fényében, amelynek célja a hulladék kihívásainak erőforrás-lehetőségekké változtatása.

A Bizottság megállapította, hogy a Bizottság a fentiek alapján nem állapította meg, hogy a Bizottság a Bizottság által a Bizottsághoz benyújtott információk alapján a Bizottságnak a Bizottsághoz benyújtott kérelmekre vonatkozó információkat figyelembe veheti. Az olyan értékes melléktermékek előállítása, mint az olaj, a szén-dioxid és a gáz, bevételi forrásokat nyit a kereslet által táplált különböző ágazatokban. A pirólizis létesítmények felépítésével és karbantartásával azonban jelentős kezdeti költségek járnak. E kihívások ellenére a fenntartható gyakorlatokból származó hosszú távú gazdasági érték potenciálisan meghaladhatja az eredeti beruházási megfontolásokat.

A gumiabroncsok pirolízisének ígéretes hatásai ellenére számos kihívással kell szembenéznie. A technológiai korlátok, például a pirolízált termékek következetes minőségének biztosítása továbbra is jelentős akadály. Ezenkívül a magas működési költségek hátráltathatják a széles körű alkalmazást, miközben a nyilvánosság által a újrahasznosítási technológiákra vetett tekintély és bizalom problémái továbbra is fennállnak. A pirolízissel kapcsolatos lehetőségek teljes kiaknázásához sürgősen javításra van szükség ezekben a területeken, hogy hozzájáruljanak a fenntartható hulladékgazdálkodáshoz. Az iparág pirolízisteknológiájában elért előrelépéseknek a kibocsátások és a környezetbiztonság tekintetében is meg kell oldaniuk a közvélemény elfogadásának és a szabályozásnak való megfelelés biztosítása érdekében felmerülő aggodalmakkal kapcsolatos problémákat.

A jövő Az abroncsok pirolízisa Technológiák

A feltörekvő technológiák alakítják a gumiabroncs-hulladék pirolízisének jövőjét. Az olyan újítások, mint a mikrohullámú pirolízissel történő elősegítés, a legelső helyen állnak, és ígéretes előrelépéseket tesznek a feldolgozási hatékonyság és az energia megőrzés terén. Ezek a technológiák potenciális előnyeit hordozzák, beleértve a feldolgozási idő csökkentését és az olyan értékes melléktermékek fokozott hozamát, mint a pirólizis olaj és a visszanyert szénfekete (rCB). A katalizálás javításai is egyre nagyobb körben szerepet játszanak, amelyek célja a reakciók szelektivitásának növelése és a végtermékek minőségének javítása.

A pirolízisszel kapcsolatos legújabb innovációk az energiafelhasználás optimalizálására és az általános hatékonyság növelésére irányulnak. Például a Molten technológia egy figyelemre méltó fejlődés, amely lehetővé teszi az energiabevitel és a folyamatparaméterek pontos ellenőrzését, növelve a pirolízisszel kapcsolatos stabilitást és következetességet. Ezek a fejlődések elengedhetetlenek ahhoz, hogy a gumiabroncspirolízist nemcsak gazdaságilag életképes, hanem környezetbarátabbá is tegyék az energiafogyasztás csökkentésével és az erőforrás-visszanyerés maximalizálásával.

A Bizottság megállapította, hogy a Bizottság a fentiek alapján nem ítélte meg a Bizottság által a Bizottság által a Bizottsághoz benyújtott kérelmekre vonatkozó válaszokat. Ez az integráció átfogóbb hulladékgazdálkodási megoldásokhoz vezethet, amelyek hatékonyan értékes energiává és anyagává alakítják át a hulladékkerékeket, és erősítik a körforgásos gazdaságot. A kerékpárhulladék pirolízisének más technológiákkal való kombinálásával hatékonyan hozzájárulhat az energia-visszanyeréshez és csökkentheti a nem megújuló erőforrásoktól való függést, így megnyitva az utat a fenntarthatóbb jövő felé.

A szabályozási környezet befolyásolása Az abroncsok pirolízisa

A gumiabroncshulladék pirolízisét szabályozó szabályozási környezet a gumiabroncshulladékok ártalmatlanításának és újrahasznosításának kezelésére irányuló szakpolitikákra alapszik. A jelenlegi szabályozások hangsúlyozzák a környezetvédelmi előírások betartását, és előírják a pirólizis létesítmények számára, hogy szigorú iránymutatásokat kövessenek a kibocsátások csökkentése és a biztonságos üzemeltetés érdekében. Ezek a megfelelőségi követelmények hatással vannak a működési költségekre, mivel a létesítményeknek a büntetések elkerülése érdekében olyan technológiákba kell befektetniük, amelyek megfelelnek a jogszabályi előírásoknak.

A szabályozás jelentős hatással van a pirólizis ágazat működési költségeire és a technológia bevezetésére. A megfelelés gyakran elősegíti a fejlett technológiák alkalmazását, ami elősegíti a kezdeti beruházásokat, de hosszú távú megtakarításokat és hatékonyságnövekedéseket eredményezhet. A tiszta technológiák prioritása révén a vállalkozások magasabb kezdeti költségekkel szembesülnek, de ezeket csökkentett működési kockázatok és jobb környezeti eredmények ellensúlyozhatják.

A jövőre tekintve a politikai változások valószínűleg szigorúbb környezetvédelmi biztosítékokat és fenntartható gyakorlatokat támogatnak. Egyre nagyobb szükség van támogató jogszabályokra a gumiabroncshulladék pirolízisének szélesebb körű alkalmazásának ösztönzése érdekében, és a környezeti előnyök növelése érdekében a hulladékból energiát előállító egyéb technológiákkal való integrációja. A várható politikai változások elősegíthetik az innovációhoz kedvezőbb környezetet, a technológiai fejlődés előmozdítását és a hulladékgazdálkodásban keletkező ökológiai lábnyomok csökkentését.

Esetleges tanulmányok: a Az abroncsok pirolízisa

A gumiabroncsok pirolízisének gyakorlati alkalmazása világszerte egyre nagyobb népszerűségre tett szert, és az Egyesült Államokban, Kínában és számos európai országban sikeres kezdeményezések nyilvánvalóak. Ezek az országok nemcsak a gumiabroncshulladék kezelésére, hanem értékes anyagok kivonására is kihasználják ezt a technológiát, ezzel bizonyítva annak gazdasági és környezetvédelmi potenciálját. Az Egyesült Államokban például pirolíziszüzemélyiségeket hoztak létre a gumiabroncsok hulladékainak újrafelhasználható anyagokban való átalakítására, mint például a szénfekete és az üzemanyagok, támogatva a helyi gazdaságokat, miközben a hulladékgazdálkodási kihívásokkal foglalkoznak.

A Bizottság megállapította, hogy a Bizottság a fentiek alapján nem állapította meg, hogy a Bizottság a fentiek alapján megállapította-e, hogy a Bizottság a fentiek alapján megállapította-e, hogy a Bizottság a fentiek alapján megállapította-e, hogy a Bizottság a fentiek alapján megállapította-e, hogy a Bizottság a fentiek alapján megállapította-e, hogy Kínában a nagyméretű pirólizis projektek jelentősen hozzájárultak a hulladékcsökkentéshez és az anyaghasznosításhoz. Az ország kezdeményezései például hatalmas mennyiségű gumiabroncs hulladékát energiává és egyéb melléktermékekké alakították újra, ami segít csökkenteni a környezeti lábnyomot és elősegíti a fenntartható fejlődést.

Az ilyen esettanulmányokból levont tanulságok rámutatnak arra, hogy milyen fontos a legjobb gyakorlatokat alkalmazni, miközben óvatosnak kell lennünk a lehetséges csapdákkal szemben. A siker kulcsszereplői közé tartozik a fejlett technológiákba történő befektetés, a környezetvédelmi előírások betartásának biztosítása és a kormányzati hatóságok és a magánvállalkozások közötti együttműködés előmozdítása. A Bizottság úgy véli, hogy a Bizottságnak a Bizottság által a Bizottságnak nyújtott támogatásokból származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereség

Az érdekelt felek közreműködése a gumiabroncshulladék pirolízisében

A kerékpár-hulladék pirolízisének sikeres végrehajtásához az érdekelt felek közötti együttműködés kulcsfontosságú, és különböző szervezetek, például kormányok, iparágak és nem kormányzati szervezetek (NGO-k) bevonásával történik. Minden érdekelt fél kulcsszerepet játszik; a kormányok kedvező törvényeket és pénzügyi ösztönzőket hozhatnak létre, az iparágak ösztönözhetik az innovációt és működtethetik az új technológiákat, míg a civil szervezetek felhívhatják a figyelmet a nyilvánosságra és támogathatják a fenntartható gyakorlatokat. A pirolízisteknológiák alkalmazásával kapcsolatos akadályok leküzdésében a közös erőfeszítések elengedhetetlenek.

A kihívások kezelése érdekében az érdekelt felek gyakran közös erőfeszítéseket tesznek, amelyek közé tartoznak a közvélemény tudatosságának növelésére irányuló kampányok és a finanszírozási támogatás biztosítása. Ezek az intézkedések célja a közösségek tájékoztatása a pirólizis előnyeiről, valamint a bevezetésének pénzügyi megvalósíthatóságának megkönnyítése. Az ilyen együttműködési kezdeményezések széles körű támogatási alapot és erőforrás-összekapcsolást biztosítanak, amelyek kulcsfontosságúak a szélesebb körű elfogadás és végrehajtás akadályainak leküzdéséhez. A partnerségek továbbá elősegítik a fenntartható gumiabroncshulladékkezeléshez elengedhetetlen technológiák és szabályozási keretek fejlesztését. Az érdekelt felek közötti szoros szövetségek felbecsülhetetlen értékűek a pirólizis műveleteiben felmerülő technológiai, gazdasági és szabályozási kihívások kezelésére szolgáló átfogó stratégiák kidolgozásában.

Végezetül: A gumiabroncshulladék pirolízisének jövője

A gumiabroncshulladék pirolízisének jövője abban rejlik, hogy képes lesz kielégíteni a fenntartható újrahasznosítási módszerek iránti növekvő keresletet. Mivel az iparágak és a kormányok elismerik a hulladék hasznos erőforrássá való átalakításának képességét, a kutatás és fejlesztés folytatásának támogatása döntő fontosságú lesz. E technológiák fejlesztésével jelentősen javíthatjuk a globális hulladékgazdálkodási gyakorlatokat, és megnyithatjuk az utat a fenntarthatóbb jövő felé.

GYIK

Mi az a gumiabroncs-hulladék pirolízise?

A kerékpár-pirolízisz egy olyan folyamat, amely a kerékeket intenzív fűtésen keresztül, oxigénmentes környezetben bontja le, hogy melléktermékeket termeljen, mint például olaj, szénfekete és gáz.

Milyen előnyei vannak a gumiabroncsok pirolízisének?

A pirolízissel csökkenthető a hulladéklerakók használata, korlátozható az üvegházhatású gázok kibocsátása, gazdasági lehetőségek jönnek létre, és támogatható az újrahasznosítási ipar értékes melléktermékek előállításával.

Milyen kihívásokkal néz szembe a gumiabroncs-hulladék pirolízise?

A fő kihívások közé tartoznak a technológiai korlátok, a magas működési költségek, valamint a közvélemény észlelésével és bizalommal kapcsolatos kérdések. A szabályozásnak való megfelelés és a kibocsátáscsökkentés szintén jelentős kihívások.

Milyen új technológiák fejlődnek a gumiabroncsok pirolízisében?

A feltörekvő technológiák közé tartozik a mikrohullámú pirolízissel támogatott és a fokozott katalizációs folyamatok, amelyek növelik a folyamat hatékonyságát és a melléktermékek hozamát.

Miért fontos a pirolízissel kapcsolatos érdekelt felek közötti együttműködés?

Az érdekelt felek közötti együttműködés fontos, mivel támogató törvények létrehozását, a technológiai innováció ösztönzését és a nyilvánosság elfogadásának biztosítását jelenti a tudatosságra juttatási kampányok és a kollektív erőfeszítések révén.

Tartalom:

- Megértés Az abroncsok pirolízisa

- A Az abroncsok pirolízisa

- A jövő Az abroncsok pirolízisa Technológiák

- A szabályozási környezet befolyásolása Az abroncsok pirolízisa

- Esetleges tanulmányok: a Az abroncsok pirolízisa

- Az érdekelt felek közreműködése a gumiabroncshulladék pirolízisében

- Végezetül: A gumiabroncshulladék pirolízisének jövője

-

GYIK

- Mi az a gumiabroncs-hulladék pirolízise?

- Milyen előnyei vannak a gumiabroncsok pirolízisének?

- Milyen kihívásokkal néz szembe a gumiabroncs-hulladék pirolízise?

- Milyen új technológiák fejlődnek a gumiabroncsok pirolízisében?

- Miért fontos a pirolízissel kapcsolatos érdekelt felek közötti együttműködés?