Mi az a Pyrolysis?

A pirolízissel a szerves anyagok újrahasznosításában játszott szerepe miatt széles körben elismert termo kémiai bomlási folyamatot végeznek. Ez a technika a anyagok magas hőmérsékletnek, gyakran 400 °C-nál magasabb hőmérsékletnek való kitettségét jelenti oxigénmentes környezetben, így megakadályozza a égést. Ez a feltétel megkönnyíti a bonyolult molekulák egyszerűbb formákba történő lebontását, mint például a szingáz, az olaj és a szilárd maradványok.

Lényegében a pirolízissel a molekulatéren lévő anyagok bomlása a hő felhasználásával történik. Az oxigén hiánya kritikus, mivel biztosítja, hogy a folyamat ne váljon oxidációba vagy égésbe, lehetővé téve a polimerek és más összetett anyagok fokozatos lebontását. Ez a felbomlás létfontosságú a hulladék, mint például a gumiabroncsok értékes másodlagos felhasználásává való átalakításához. Termékek mint például gázok és olajok.

A pirolízissel jelentős szerepe van a hulladékgazdálkodásban és az energiahasznosításban, mivel hozzájárul a hulladéklerakók csökkentéséhez, és környezetbarát ártalmatlanítási módszert biztosít olyan anyagok számára, mint a hulladékkerék és a műanyag. Ez a folyamat értékes melléktermékeket hoz létre, miközben minimalizálja a környezeti lábnyomokat. A pirolízisz két fő módszere a tétel- és folyamatos folyamat. A sorozatpirolízissel a anyagok diszkrét egységekben vagy "tárgyakban" dolgoznak fel, lehetővé téve a terhelés, feldolgozás és kirakodás tervezett ciklusait. A folyamatos pirolízisz közben folyamatos, zökkenőmentes folyamatot jelent, amely a nagyobb mértékű hulladékfeldolgozáshoz optimalizálja a teljesítményt és a működési hatékonyságot.

A Az abroncsok pirolízisa A folyamat

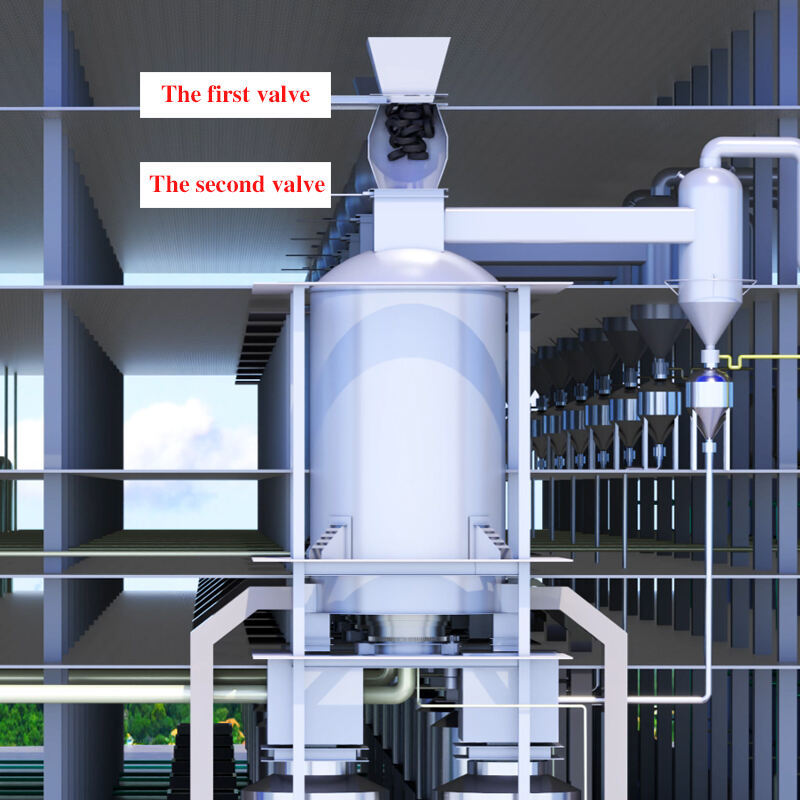

A gumiabroncs-hulladék pirolízisének folyamata a nyersanyagok gondos előkészítésével kezdődik. A hatékonyság optimalizálása érdekében a gumiabroncsok méretét csökkenteni kell, és tisztítani kell a nem kívánt anyagokat, például a szennyeződéseket és a törmelékeket. A méret csökkentése nemcsak megkönnyíti a kezelést és a reaktorba történő beszerzést, hanem növeli a hőnek kitett felületet is, ami fokozza a pirólizis reakciót. A nyersanyagok tisztasága biztosítja, hogy a vegyi reakciókat nem befolyásolják a szennyező anyagok, ezáltal javul a termés hozamának és minőségének szintje.

A fűtési fázis során a gumiabroncsok pontos hőmérsékleti profilokat kapnak, általában 500°C-nál magasabb hőmérsékleteket. Ez a fázis döntő szerepet játszik a pirolízisszel kapcsolatos hatékonyság és teljesítmény meghatározásában. Ezekben a magas hőmérsékleteken, oxigén hiányában a gumiabroncsok pirolízisszölőolajra, gázokra és szénfekete szénre bomlanak. A különböző hőmérsékletek és fűtési sebességek jelentősen befolyásolhatják e termékek összetételét és hozamát. Például a magasabb hőmérséklet növelheti a gáztermelést, míg a mérsékelt hőmérséklet optimalizálhatja az olajkészüléket.

A pirolízisszel kapcsolatos reakciófázisok során a gumiabroncsanyagok értékes melléktermékekké alakulnak át. A gumiabroncsok összetett polimer szerkezete egyszerűbb molekulákra bomlik, ami pirolízisejtet, nem kondenzálható gázokat és szilárd széneket eredményez. Az olajat tovább finomíthatjuk és alternatív üzemanyagként használhatjuk, míg a szilárd szén, amely gyakran szénben gazdag, különböző ipari alkalmazásokban hasznosítható.

A végső szakaszban a hűtő- és a termékkivonási módszerek biztosítják a különböző pirólizis frakciók hatékony elválasztását. A pirolízisszállítmányok folyékony olajjá sűrítéséhez és a fennmaradó éghető anyagok esetleges újrafelhasználás céljából történő hasznosításához hatékony hűtőrendszerek elengedhetetlenek. A megfelelő kezelés és tárolás elengedhetetlen az ilyen pirólizis termékek forgalmazhatóságának fenntartásához, és annak biztosításához, hogy megfeleljenek a végfelhasználók számára szükséges minőségi előírásoknak. A folyamatok gondos kezelése létfontosságú a gazdasági haszon maximalizálásához és a fenntartható hulladékgazdálkodási gyakorlathoz való hozzájáruláshoz.

A Az abroncsok pirolízisa

A gumiabroncsok pirolízisének folyamata számos értékes terméket állít elő, amelyek közül az egyik a legfontosabb, a tüzelőolaj. Ez az olaj, amelyet gumiabroncsból származó olajnak (TDO) neveznek, alternatív energiaforrásként szolgál, mivel magas hőtartalma van, ami összehasonlítható a hagyományos dízelrel. A TDO ipari környezetben fűtőeszközökre vagy akár belső égésű motorokra is felhasználható, így olyan megújuló megoldást kínál, amely összhangban van a fosszilis tüzelőanyagoktól való függőség csökkentésére irányuló globális erőfeszítésekkel.

A gumiabroncs pirolízisének egy másik jelentős terméke a szénfekete, amely sokoldalú anyag, széles körben alkalmazható. A szénfekete széles körben használják megerősítő töltőanyagként a gumiabroncsok gyártásában, így növelve a tartósságot és a teljesítményt. A gumiabroncsgyártáson túlmenően a festékek, bevonatok és műanyagok fő összetevője is, ahol színező és tartósságosabb.

A felhasznált acél egy másik értékes melléktermék a gumiabroncs pirolíziséből, amely jelentős gazdasági előnyt jelent. A kivont acél újrahasznosítható és újrahasznosítható különböző iparágakban, ami hozzájárul a fémtermék iránti kereslet csökkentéséhez. A Bizottság megállapította, hogy a Bizottság nem vizsgálta a fentiek alapján a Bizottság által a Bizottsághoz benyújtott információk alapján megállapított, hogy a Bizottság a fentiek alapján megállapította, hogy a Bizottságnak nem kell vizsgálnia a fentiek alapján megállapított, a Bizottság által a Bizottsághoz benyújtott, a Bizottság által a Bizottsághoz benyújtott, a Bizottság által a Bizottsághoz

A Az abroncsok pirolízisa

A kerékpárhulladék pirólizis jelentős környezeti előnyt jelent, mivel csökkenti a hulladéklerakókba juttatott hulladékot és az üvegházhatású gázok kibocsátását. A Bizottság megállapította, hogy a Bizottság a Bizottság által a Bizottságnak benyújtott információk alapján megállapított, hogy a Bizottság a Bizottság által a Bizottságnak benyújtott információk alapján megállapított, a Bizottság által a Bizottságnak benyújtott információk alapján megállapított, hogy a Bizottságnak a Bizottság által benyújtott információk alapján megállapított, a Bizottság által a Bizottságnak benyújtott információk alapján megállapított, hogy A hagyományos hulladékkezelési módszerek elterjedése révén a pirolízissel a hulladéklerakással és a hulladékégetéssel kapcsolatos negatív környezeti hatások minimálisra csökkenthetőek, így megvédve az ökoszisztémákat és csökkentve a szennyezést.

A Bizottság megállapította, hogy a Bizottság a fentiek alapján nem állapította meg, hogy a Bizottság a fentiek alapján megállapította volna, hogy a Bizottság a fentiek alapján nem ítélte meg a Bizottság által a Bizottságnak benyújtott kérdést. Az iparágak hosszú távú költségmegtakarítást érhetnek el azáltal, hogy újrahasznosított anyagokat használnak, mint például pirolítica olajat és szénfeketét, amelyek a gyártási folyamatokban a szűz erőforrásokat helyettesíthetik. A gazdasági előnyök kiterjednek az acél-visszanyerési iparágra is, ahol a gumiabroncsokból nyert acél piacot talál az építőiparban és a gyártásban, hozzájárulva a gazdasági növekedéshez és az erőforrás-hatékonysághoz.

A Bizottság megállapította, hogy a Bizottság a fentiek alapján nem állapította meg, hogy a Bizottság a fentiek alapján megállapította volna, hogy a Bizottság a fentiek alapján nem ítélte meg a Bizottság által a Bizottságnak benyújtott kérdést. A folyamat pirolízisben előállított olajat és gázt termel, amelyeket megújuló energiaforrásokként lehet felhasználni, csökkentve a fosszilis tüzelőanyagoktól való függőséget. Ez az energia-visszanyerési szempont hangsúlyozza a pirólizis fenntarthatósági potenciálját, amely összhangban van az alternatív és tisztább energiaellátási megoldások felé való átállás globális erőfeszítéseivel, biztosítva a világ iparágainak és közösségeinek fenntarthatóbb jövőjét.

Kihívások és korlátok

A kerékpár-hulladék pirolízise a lehetséges előnyei ellenére számos kihívással és korlátozással néz szembe. Az egyik jelentős akadály a gumiabroncs-hulladék piróliziséhez kapcsolódó szabályozási és megfelelőségi kérdések, amelyek magukban foglalják a szükséges környezetvédelmi engedélyek megszerzését és a helyi előírások betartását. A szabályozási ellenőrzés késleltetheti a projekteket és növelheti a költségeket, mint azt a régiókban tapasztalható, ahol a környezetvédelmi csoportok aggodalmát fejezték ki a pirolízisszerkezetekkel kapcsolatos szennyezés és biztonsági kockázatok miatt.

A műszaki korlátozások a gumiabroncshulladék pirolízisével kapcsolatos kihívásokat is jelenthetik. A jelenlegi technológiák a hatékonyság és a skálázhatóság terén küzdhetnek, korlátozva a széles körű alkalmazást. A pirolízissel kapcsolatos folyamatos kutatás és fejlesztés elengedhetetlen a folyamatok hatékonyabbá és költséghatékonyabbá tételének javítása érdekében. Az ezen a területen megvalósuló innovációk potenciálisan csökkenthetik a termelési költségeket és javíthatják a folyamat környezeti hatását.

A piaci kereslet és a gazdasági tényezők egy újabb összetettséget is hozzák hozzá. A pirolízisszel előállított termékek jövedelmezőségét erősen befolyásolják a globális olajárak és a gazdasági körülmények, amelyek befolyásolhatják a piaci keresletet és az árstabilitást. Ez a függőség megnehezítheti a pirólizáló üzemek gazdasági életképességének fenntartását, különösen ingadozó piacokon. A fenti kihívások kezelése elengedhetetlen a gumiabroncshulladék pirolízisének fenntartható megoldásként történő előmozdításához.

Innovációk a pirolízisteknológiában

A pirolízis technológiájában elért legújabb fejlődés jelentősen javította a gumiabroncshulladék pirolízisének hatékonyságát és eredményességét. A reaktor tervezésében bekövetkezett újítások, mint például a jobb hőelosztás és a javított keverőmechanizmusok, optimalizálták a gumiabroncsok értékes melléktermékekké történő lebontását. Az automatizálás tovább javította a működési pontosságot, csökkentette az emberi hibákat és növelte a teljesítményt. A tanulmány szerint a Az analitikai és alkalmazott pirolízist vizsgáló folyóirat , ezek a technológiai fejlesztések növelték a termék hozamát és javították a gumiabroncsokból származó olaj minőségét [Berrueco et al., 2005].

A pirólizis létesítmények biztonságának biztosítása elsődleges célkitűzéssé vált. Az új kockázatkezelési stratégiák közé tartozik a potenciális veszélyek felismerésére és az automatikus leállítási eljárások megindítására szolgáló valós idejű megfigyelési rendszerek használata. Ezek a fejlődések elengedhetetlenek a munkavállalók védelme és a környezetre gyakorolt hatás minimalizálása szempontjából. Az egészségügy és a biztonság programjai integrálták ezeket a technológiai fejlesztéseket, hogy jobban kezeljék a kibocsátásokat és felelősségteljesen kezeljék a melléktermékeket.

A jövőre tekintve a pirolízist más hulladékgazdálkodási megoldásokkal, például az újrahasznosítási és energia-visszanyerési rendszerekkel való integráció ígéretes tendenciát mutat. A jövőbeni innovációk várhatóan az energiahatékonyság növelésére és a pirolízist megújuló energiaforrásokkal való kombinálásra összpontosítanak. Ez összhangban van a fenntartható fejlődés felé irányuló globális törekvéssel. A technológia fejlődésével a pirolízissel kapcsolatos ismeretek és alkalmazások valószínűleg bővülnek, és ezáltal a pirolízissel kapcsolatos ismeretek és alkalmazások a körforgásos gazdaság stratégiáinak kulcsfontosságú szereplőjeként tovább szerepelnek.

A pirolízisszel előállított termékek alkalmazása

A pirolízisszel különböző termékeket hoznak létre, amelyek széles körben alkalmazhatók az iparágakban. A pirolízisszel előállított olaj például értékes erőforrás a villamosenergia-termelésben, a kazán üzemanyagként is felhasználható, és fontos szerepet játszik az aszfalt előállításában. Ez a sokoldalú képesség hangsúlyozza annak jelentőségét a hagyományos fosszilis tüzelőanyagoktól való függőség csökkentésében. Fontos, hogy elismerjük a pirólizisolaj alkalmazkodóképességét több ágazatban, elősegítve a fenntartható energiaellátásokat és hozzájárulva az ökológiai egyensúlyhoz.

A gumiabroncsok pirolíziséből nyert szénfekete újrahasznosítási alkalmazásokat talál a különböző gyártási folyamatokban. Ez magában foglalja a gumi, tinták, tinta és festékek gyártásában való használatát, ahol erősségi szerként nagyra értékelik tulajdonságait. A újrahasznosított szénfekete piacok kialakulása kiemeli az ilyen anyagok ellátási láncba történő beépítésének gazdasági potenciálját és környezeti előnyeit. Ez az integráció összhangban van a globális fenntarthatósági célokkal, a körforgásos gazdaságok előmozdításával és az ökológiai lábnyomok csökkentésével.

A pyrolízissel előállított acél jelentős gazdasági előnyt is nyújt az építészetben és a gyártásban történő felhasználásakor. A vas újrahasznosítása nemcsak a természeti erőforrásokat takarítja meg, hanem csökkenti az energiafogyasztást is, mint az új acél nyersanyagokból történő előállítása. A gazdasági előnyök tovább terjednek, mivel csökkentik a termelési költségeket és támogatják a fenntartható gyakorlatokat. Összességében véve a pirólizis technológia létfontosságú szerepet játszik a hulladék életképes erőforrássá való átalakításában, a hatékonyság növelésében és a környezeti hatás csökkentésében.

A gumiabroncshulladék pirolízisének jövője

A gumiabroncs-hulladék pirolízisének jövője jelentős piaci lehetőségeket és növekedési potenciált kínál, amelyet az iparág kulcsfontosságú szereplői és a feltörekvő induló vállalkozások hajtanak. Számos vállalat innovatív pirólizis technológiákba fektet, hogy növelje a hatékonyságot és a termelést. Ez a folyamat a már ismert hulladékgazdálkodási vállalkozások és az új szereplők figyelmét is felhívta, akik a hulladék energiává válásának lehetőségéről szeretnének profitálni. A fenntartható gyakorlatokra irányuló növekvő kereslet olyan iparágakban, mint a közlekedés és a gyártás, tovább ösztönzi a pirólizis technológia alkalmazását.

A szakpolitikai hatások döntő szerepet játszanak az iparág kialakításában. A kormányok világszerte szabályozásokat vezetnek be a hulladék újrahasznosításának és hasznosításának előmozdítására, ami pozitív hatással van a pirolízissel kapcsolatos növekedésre. A fentiek alapján a Bizottság megállapítja, hogy a Bizottság a Bizottság által a Bizottságnak nyújtott támogatásokból származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó nyereségekből származó ny

A hosszú távú fenntarthatósági célok a pirolízist a körforgásos gazdaság kulcsfontosságú szereplőjeként teszik ki, és segítik a fosszilis tüzelőanyagoktól való függőség csökkentését. Mivel az iparágak környezetbarátabb gyakorlatokra térnek, a pirolízissel jelentős mértékben hozzájárulhat a hulladék értékes erőforrássá való átalakítása. A folyamat nemcsak mérsékli a környezeti hatásokat, hanem összhangban van a szén-dioxid-kibocsátás csökkentésére irányuló globális erőfeszítésekkel és a fenntartható növekedés kezdeményezéseinek támogatásával. A folyamatos innováció és a politikai keretekhez való igazodás révén a gumiabroncshulladék pirólizis jelentős mértékben hozzájárul a környezetbarátabb jövőhez.

GYIK

Melyek a kerékhulladék pirolízisének főbb termékei?

A kerékpár-hulladék pirolízissel elsősorban kerékből származó olajat (TDO), szénfeketét és visszanyert acélt állítanak elő, amelyek alternatív energiaforrások, erősítő anyagok és újrafeldolgozható anyagokként szolgálnak.

Milyen előnyei vannak a pirólizis használatának a hulladékgazdálkodásban?

A pirolízissel a hulladéklerakókban keletkező hulladékok száma csökken, hozzájárul az energia hasznosításához, csökkenti az üvegházhatású gázok kibocsátását, és támogatja az anyagok újrafeldolgozását, összhangban a körforgásos gazdaság elveivel.

Van-e környezeti probléma a pirolízissel kapcsolatban?

Bár a pirolízissel csökkenthető a környezetszennyezés a hulladéklerakással összehasonlítva, a kibocsátások és a biztonsági előírások tekintetében szabályozási ellenőrzéssel kell szembenéznie, ami a kockázatok mérsékléséhez gondos kezelést igényel.

Hogyan befolyásolja a pirolízisteknológia az energia fenntarthatóságát?

A pirolízisteknológia növeli az energia fenntarthatóságát a hulladékanyagok olyan megújuló energiaforrásokba való átalakításával, mint a pirolízishízes olaj és gáz, ezáltal csökkentve a fosszilis tüzelőanyagok függőségét.

Milyen kihívásokkal küzd a gumiabroncshulladék pirolízissel történő alkalmazása?

A kihívások közé tartozik a szabályozási előírások betartásának elérése, a technológiai hatékonyság, a piaci kereslet változékonysága és a pirólizáló üzemek változó piacokon való gazdasági életképességének biztosítása.

Tartalom:

- Mi az a Pyrolysis?

- A Az abroncsok pirolízisa A folyamat

- A Az abroncsok pirolízisa

- A Az abroncsok pirolízisa

- Kihívások és korlátok

- Innovációk a pirolízisteknológiában

- A pirolízisszel előállított termékek alkalmazása

- A gumiabroncshulladék pirolízisének jövője

-

GYIK

- Melyek a kerékhulladék pirolízisének főbb termékei?

- Milyen előnyei vannak a pirólizis használatának a hulladékgazdálkodásban?

- Van-e környezeti probléma a pirolízissel kapcsolatban?

- Hogyan befolyásolja a pirolízisteknológia az energia fenntarthatóságát?

- Milyen kihívásokkal küzd a gumiabroncshulladék pirolízissel történő alkalmazása?